Electrical Wiring and Home Insurance in Vancouver

Knob and Tube, Aluminum, 60 Amp Service and DIY

Buying any home is a big step only a lucky few seem to be able to afford in Vancouver these days. Even fewer are lucky enough to purchase or build a new home, that leaves the majority of us looking at and living in older homes. When it comes to the electrical wiring in older homes, there are a few key things to look out for that can lead to some expensive issues down the road if they go unnoticed. The first three are something we have all heard of; Knob and Tube Wiring, Aluminum Wiring and a 60 Amp service. The final is something most people and home inspectors often look over, and that is unlicensed DIY renovations.

Many homeowners are currently living with one of these conditions in their home and do not even know it! The worst part is that they have been paying insurance for a long time and if reported incorrectly, it can actually void your coverage in certain circumstances!

We have gone into a home that has been passed down through generations, that is fully wired with knob and tube and the current homeowners had no idea! After looking through their policy, we found out they have not been covered for the last 15-20 years of paying! When it comes to insurance, thinking you can lie to your broker about some unlicensed wiring can lead to you losing your home and not having any coverage if anything was to ever happen. The best thing to do is contact a licensed professional and have the proper upgrades done. You can read about these upgrades in our article on how to properly fix old wiring.

Knob and Tube Wiring

Knob and Tube wiring was the first form of residential wiring commonly found in homes ranging up to the 1950’s. Knob and Tube is commonly referred to as the most dangerous type of wiring, and for the most part this holds true in a majority of installations we come across today. But back when these systems were being installed, they were a bullet proof way of wiring a home! These homes were built with very few lights and receptacles, and the demand put on these systems was very low compared to todays electrical usage.

Knob and Tube systems were called such because of the ceramic knobs and tubes that were used to hold the wires off the wood studs and carry the conductors through the joists. All joints were made by soldering a conductor onto a main feeder without actually cutting through the main feeder. This leads to a very strong type of connection with hardly any voltage losses throughout the circuit.

After knob and tube was phased out, electricians switched to a type of wiring called NMD1, in our opinion, this is the worst type of wiring you can have in your home. NMD1 is the first “cable” type of wiring used in homes and had the hot and neutral wires together in the same jacket, commonly found in houses built between 1950 and 1962. Splices were made similar to those that we make today and “daisy chaining” of devices became the norm. Both NMD1 and Knob and Tube are ungrounded forms of wiring and were terminated into fuse boxes rather than breaker boxes which were commonly not grounded at all.

The most dangerous part of knob and tube wiring is the fact that it has been tampered with over the last 50 years and many times by unlicensed electricians, or licensed contractors who do not know how to safely work on these systems. Simply put, knob and tube does not cause fires, the DIY work and deterioration of the conductors over time does.

Unfortunately, the same cannot be said for NMD1, although unlicensed contractors and deterioration is a big reason for failures, there are bigger issues that arise with this type of system. Having the hot and neutral wires in the same jacket without a ground wire make it easier for short circuits and arcing to happen. Not to mention that rodents absolutely love the taste of the NMD1 insulation, greatly increasing the chances of fires.

Aluminum Wiring

Aluminum wiring became popular in homes built between 1965 and up to 1975 with a few straggling homes leading up to the 80’s. The major reason for the switch to aluminum wiring between the years 1965-75 is because of the rising costs of copper due to the influx of bullet manufacturing for the Vietnam war effort. With the war ending in 1975, and copper prices returning to reasonable levels and a large number of fires and deaths occurring, copper wiring came back into popularity and aluminum was quickly phased out of use for regular branch circuits. Although being phased out, aluminum wiring is still commonly used today, but only when it comes to larger cables like the ones used for your electrical service or feeders for sub panels and garages. Some contractors are still using it as the feeder for electric ranges, but our opinion is that this should be wired in copper.

There is nothing inherently wrong with aluminum wiring when it is installed and maintained properly, the key words being installed and maintained properly! Aluminum has a few characteristics which lead it to be not ideal of a conductor as copper. These were first noticed in homes due to flickering lights, warm cover plates on switches and even burning plugs and wires!

First is the fact that aluminum oxidizes as soon as it is exposed to oxygen. Just like rust forms on steel in a red colour and green on copper, rust on aluminum appears as white. The key difference is that green copper oxidation is still electrically conductive while the white oxide that forms on aluminum is not a good conductor of electricity. By interfering with the flow of electricity, this causes overheating and eventually fires. This problem is solved by using an anti-oxidation gel like compound that eats through the oxide and allows the electricity to flow without issues.

The second issue with aluminum wiring is something called cold flow or creep. Once an aluminum wire is torqued under a screw or spliced with other wires, it slowly relaxes and becomes a loose connection. As electricity flows through the circuit (amperage equals heat) and then cools when not in use, the aluminum expands and contracts at a greater rate then copper, leading to loose connections. Loose connections lead to air gaps, oxidizing, increased heat, arcing and finally fire.

The third issue with aluminum wiring is the fact that aluminum as a mineral is naturally soft. Electricians who are not used to working with aluminum would scrap, dent, scratch or crush the conductors which would lead to local hot spots in the wire itself. Hotspots lead to increased creep, loose connections, arcing….. etc.…. etc.….

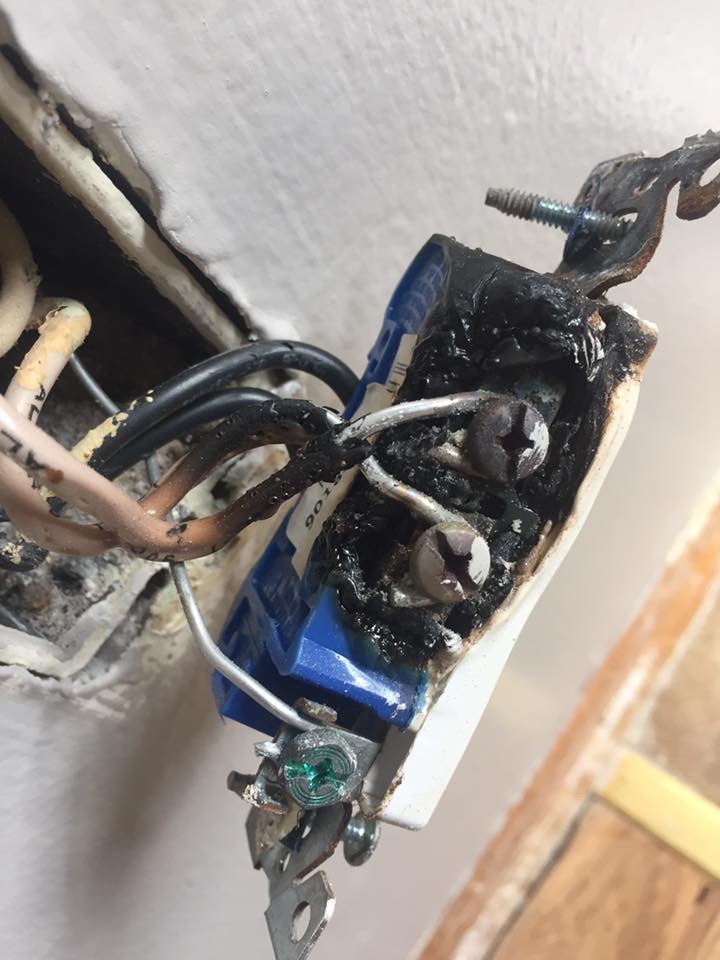

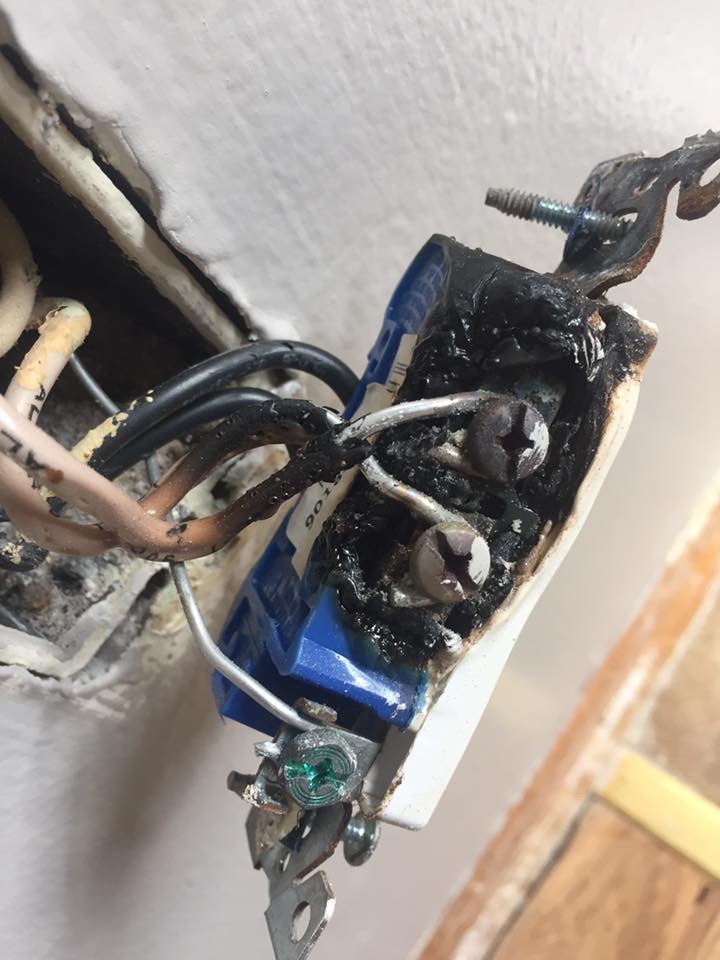

The final issue with aluminum wiring we see in todays homes is the DIY or handyman work. Many people, even most electricians, do not have the proper training or experience to work with aluminum wiring and end up creating more issues then what was originally installed. The biggest mistake we see in almost every home with aluminum is that someone along the way has upgraded the old, aluminum rated, receptacles and switches with new decora finishing’s. Unfortunately, the new finishing’s made today are not rated for use with aluminum wiring and compound the issues we were already seeing. The biggest difference between the original devices is that the terminal screws and plates were made out of brass, which has a very similar temperature coefficient as aluminum and copper. Today’s devices, although they look like brass, are made out of steel and have a temperature coefficient closer to copper, but far away from aluminum. This larger difference in temperature coefficient is what compounds the issues and leads to house fires.

If you are unsure of whether your home has aluminum wiring or not, call in an electrician to assess your home and ensure what type of wiring you have.

60 Amp Service

Beginning in the 1970’s, any home over 80 square meters (861 square feet) was required to have a minimum of a 100-amp service. Prior to this, 60-amp services were very common as most homes had very few electrical loads. Many older homes did not have cloths dryers, had gas or oil heating, and possibly an electric range if it was not natural gas. If the home is really old, a wood burning stove. These pre- 70’s homes commonly had a single light fixture in the kitchen and dining room, possibly a switched lamp plugs in the living room, and lucky to see ceiling fixtures in the 2 or 3 bedrooms. There really were no electrical demands on these homes, unlike the luxuries we live with today.

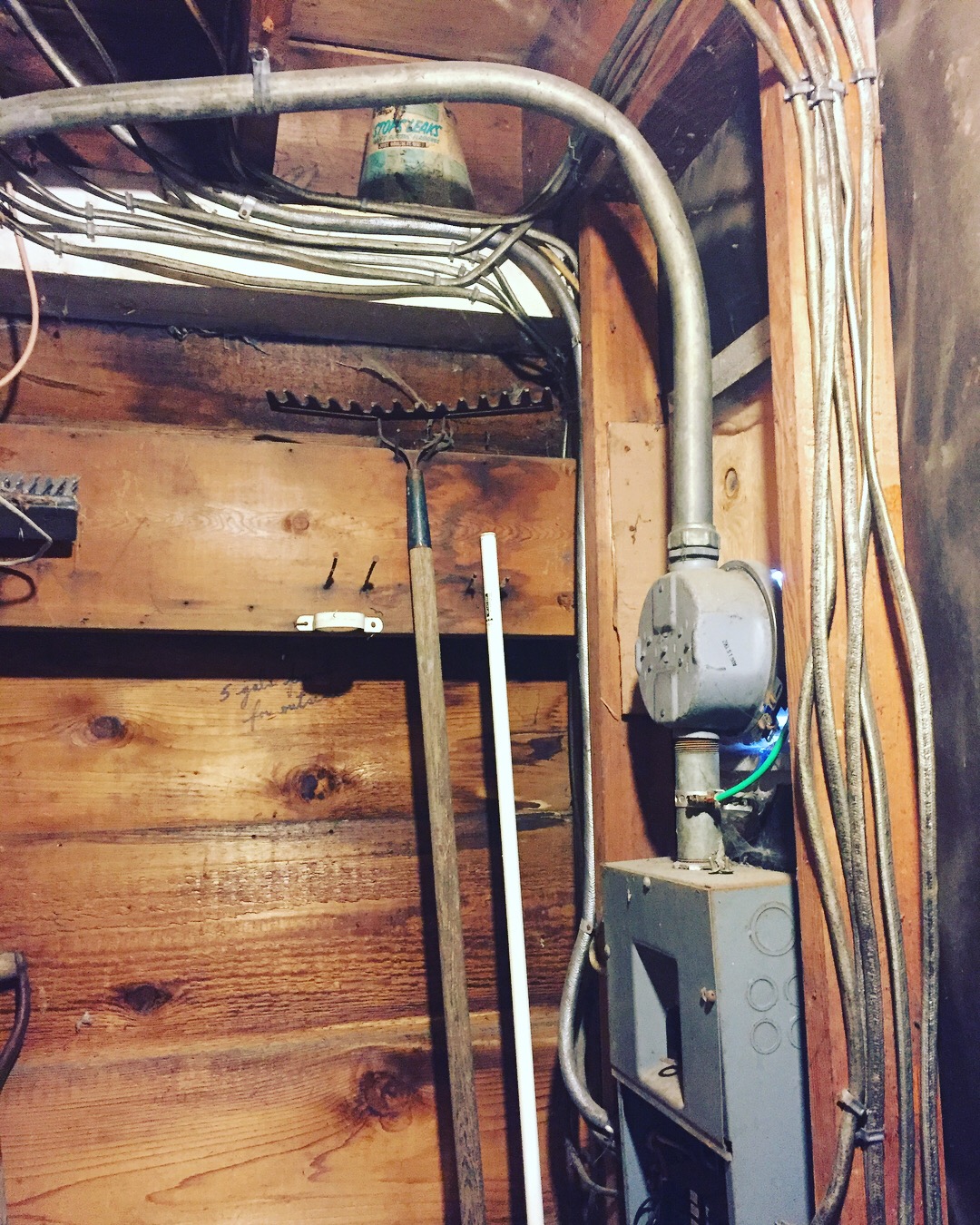

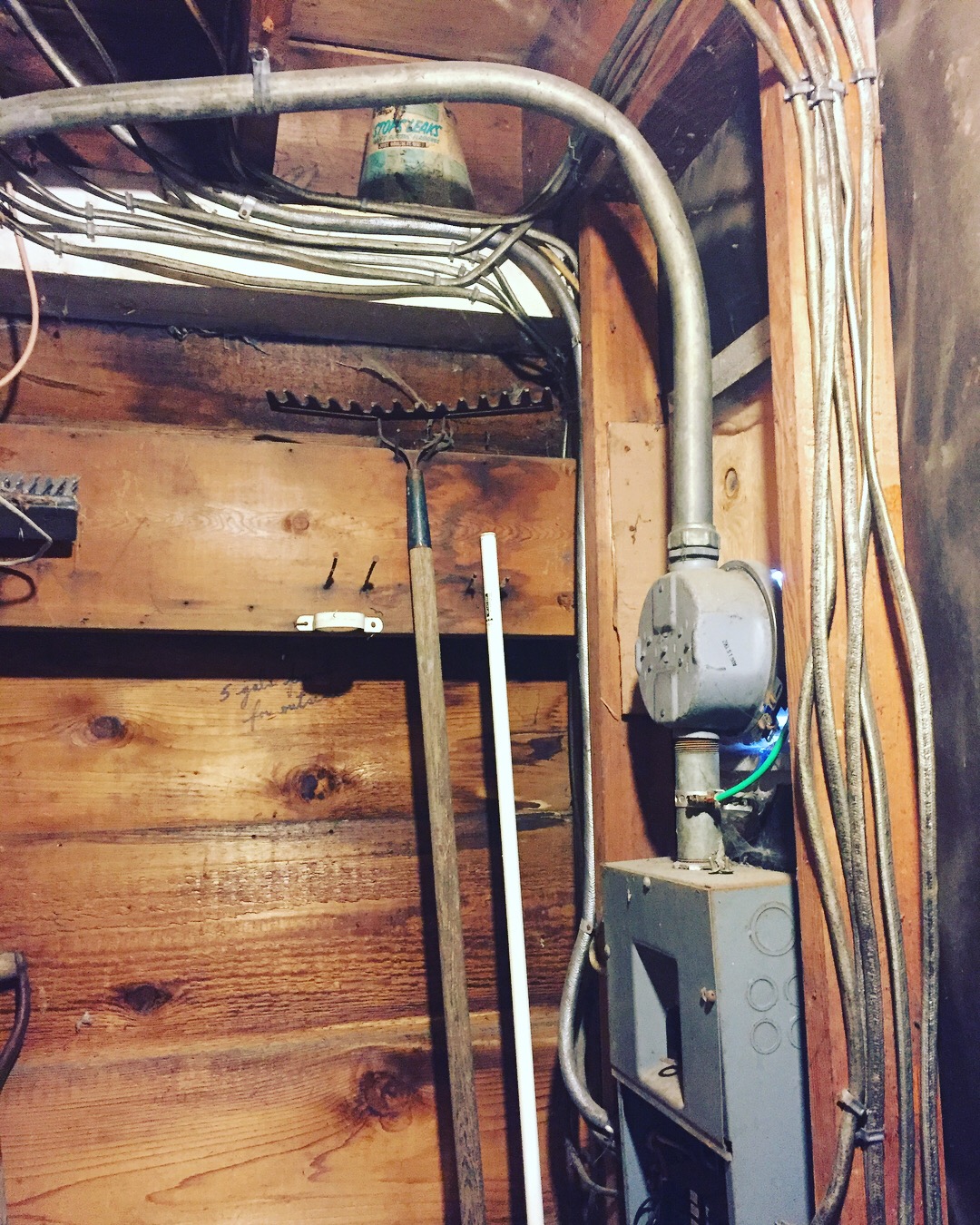

With a majority of these older homes being renovated and upgraded, the electrical panels simply did not have enough room for all the added loads. Many contractors would simply pull out the old panel and put in a larger 100 or even 200-amp panel, thinking everything would be ok as they now had more spots in the panel. The danger with having such large panels is that the main service wires leading out to the BC Hydro supply are not protected by anything! The main breaker wont trip as its sized for much larger cables, and the service conductors just get hotter and hotter until they finally melt the insulation and short out. By not having any protection upstream, this short would only be stopped by the fuses on the utility pole, which would most likely lead to damage of the utility’s cables, transformers and other equipment.

The easiest way to check your service size is to call your local municipality and ask if any electrical permits have been pulled on the home and what the scope of work these permits encompassed. If you have suspicions that there might be something wrong, have an electrical contractor remove the cover to the live wires and double check the actual size and material of the main feed. Most homes built today automatically have a 200-amp service installed as the cost increases are marginal compared to a 100-amp service. As of the latest 2018 Canadian Electrical Code, a full 200-amp service requires a 250 MCM aluminum wire or a 4/0 Copper wire. Although 4/0 aluminum can still be used for a 200-amp service (Table 39 exemptions), the panel must be clearly labeled to have a maximum calculated load of up to 189 amps. We strongly believe that a contractor still using 4/0 aluminum for the main service is really looking to cut corners as the savings in wire costs is less than $20 overall.

DIY Electrical and Renovations

As we have already covered the big three topics that home insurance providers look for, we always add in the biggest culprit of electrical fires. That is the DIY and unlicensed electrical work and renovations done in most older homes. If you walk into any home built pre- 1980’s with an underground basement (especially in Vancouver) you are guaranteed to find a basement suite or maybe even two! As home prices have sky rocketed in the last 10 years, these basement suites were an easy way to add value to a home and make it more appealing to buyers that needed the extra rental income.

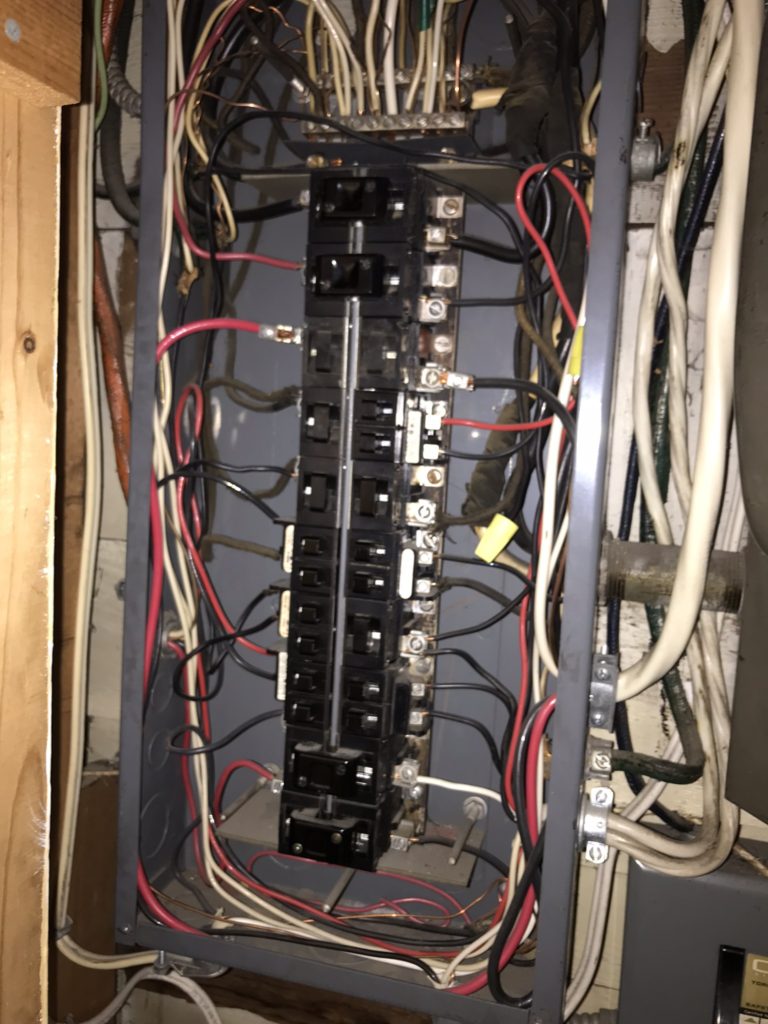

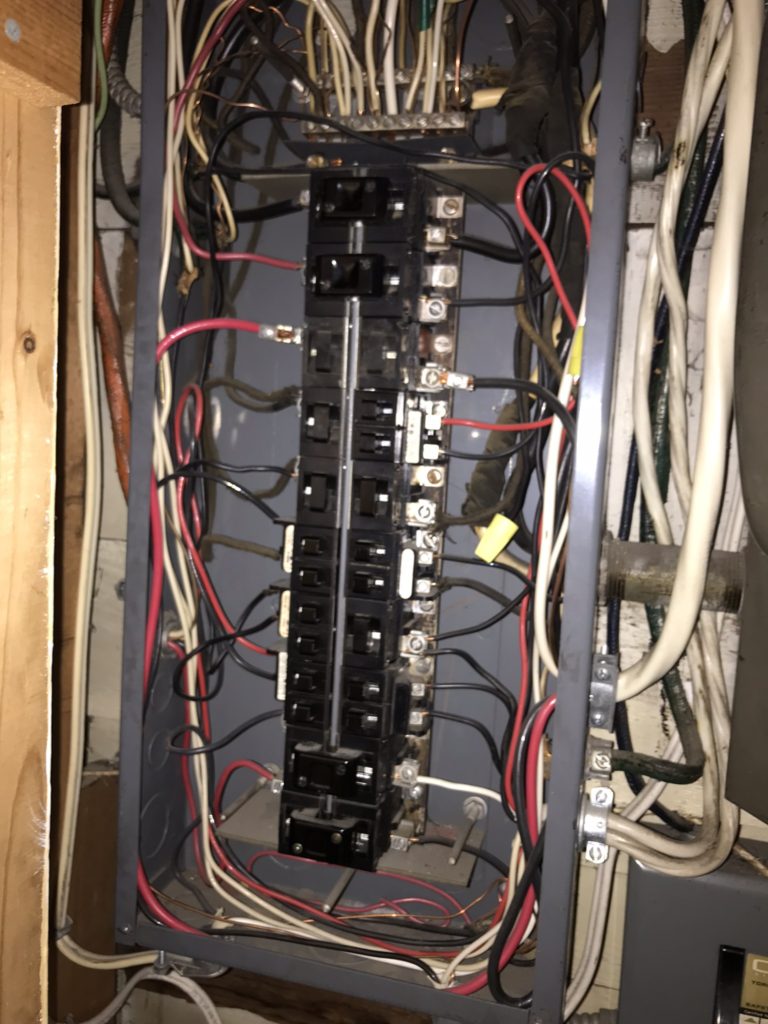

The unfortunate truth is that a majority of basement suites and renovations were done illegally and without proper permits. By not having proper permits and inspections, these handyman specials were completed by skipping over proper code rules and taking A LOT of short cuts. Some common issues we find are; hidden junction boxes, over loaded circuits, ungrounded circuits, and over all very poor workmanship. In the older homes that may have a 60-amp service, aluminum wiring or knob and tube, this poor workmanship and lack of inspections leads to any potential issues being; compounded, covered up and left looking brand new.

We have found countless homes where the homeowner believed the knob and tube wiring had been removed, and yet our tests reveal that a majority of the house was not re-wired and only made to look like everything was new.

Homeowners see new finishing’s throughout the house, and see a beautifully renovated kitchen and bathroom, yet fail to see the aluminum wiring that is hiding behind the walls that has not been properly upgraded and examined.

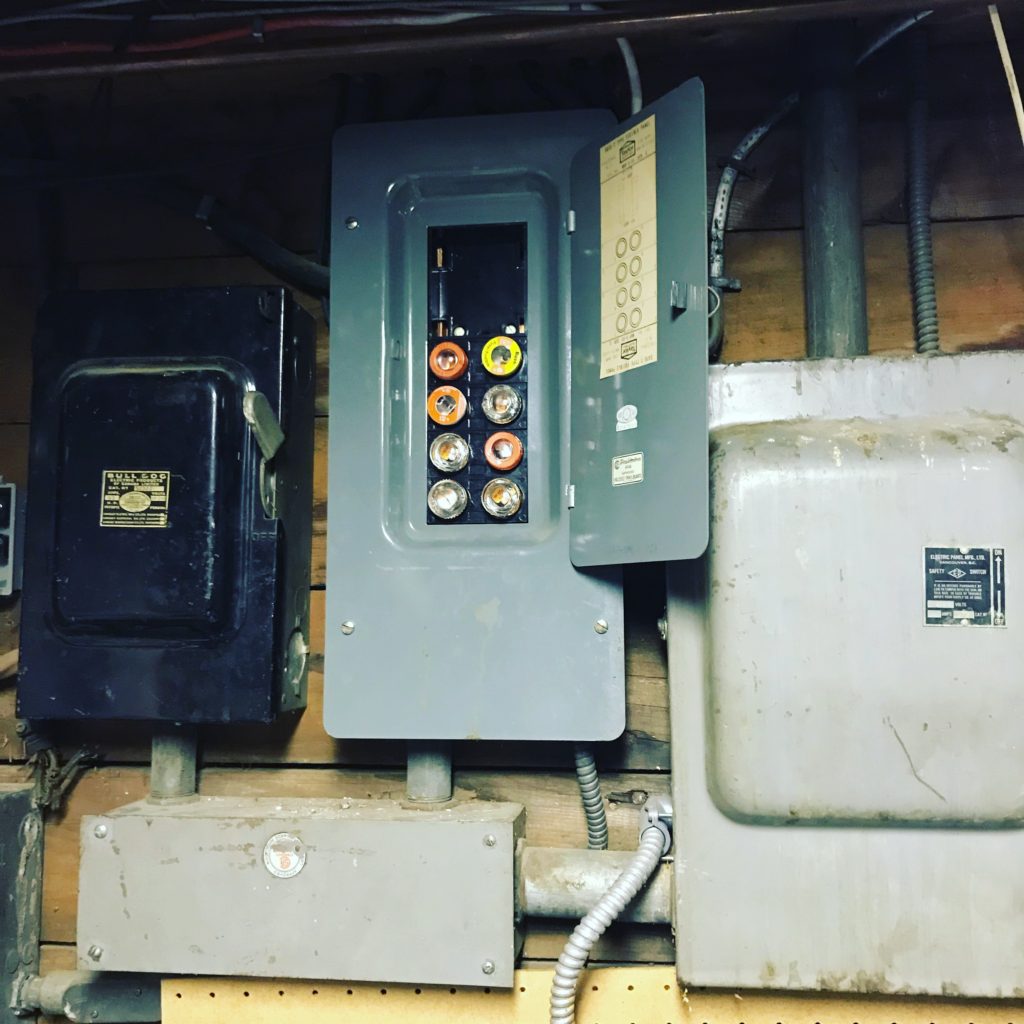

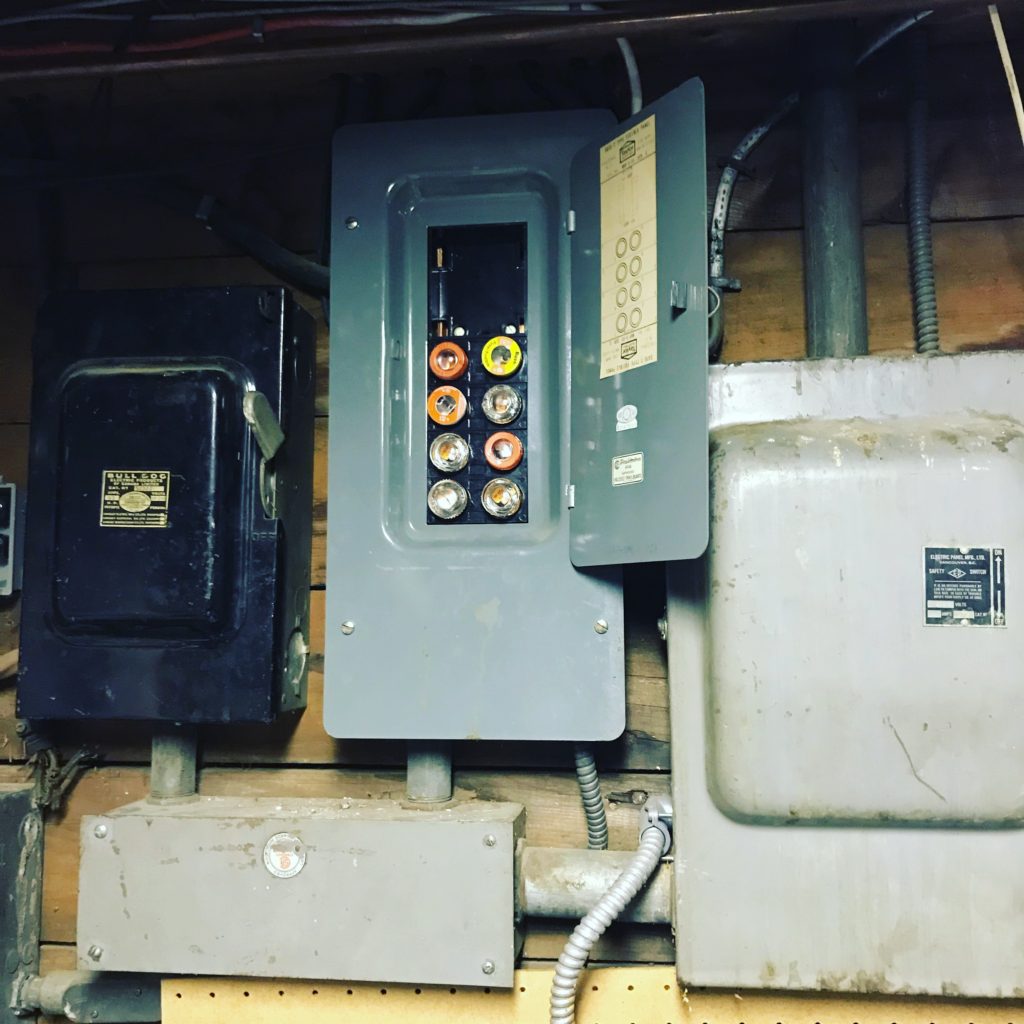

When you see a brand-new panel in the basement, most assume a service upgrade has taken place, but what actually happened was just a quick (and illegal) panel swap.

If you have any doubts about your home, about the home you are looking to purchase, or the work that was done on your home, we strongly recommend hiring a licensed contractor who specializes in electrical assessments to properly test your system and ensure what is happening behind your walls. If you want to read more before hiring a contractor, read our post on how to properly fix old electrical wiring.